04 January 2022

Capturing More N from Cattle Slurry

With fertilizer prices at all-time highs cattle slurry will be a key resource on farm to reduce the impact of high N, P & K prices. Mark Plunkett, Teagasc, Johnstown Castle, Co Wexford and Francis Quigley, Machinery Specialist, Kildalton College explain how to achieve this

Retaining more slurry N results in a larger proportion of N from slurry to grow grass in the early part of the year. This will provide opportunities to reduce chemical fertilizer N inputs in 2022. The use of LESS (Trailing shoe / band spreader) is one of the key technologies available to meet our national ammonia-gas reduction target between now and 2030.

Step 1. Know the value of Slurry N, P K & S

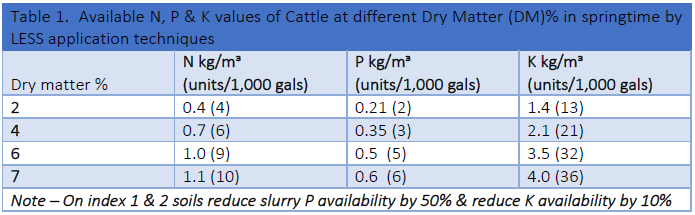

We now must look at cattle slurry the same as bag fertilizer and focus on utilising all the major nutrients as efficiently as possible. Low emission slurry spreading techniques helps supply a larger proportion of the crops total N requirements than ever before. This change delivers a double dividend in that it helps to reduce agricultural emissions and our overall farm fertilizer bill annually. The first step to utilising the nutrients in slurry is to know how much N, P & K is in each 1,000 gallons of slurry. On farms where dirty water / parlour washings are entering the slurry tank a more dilute slurry is available. Table 1 below shows the available fertilizer values (N, P & K) for a range of cattle slurries at different dry matters(DM) applied by LESS.

Typical cattle slurry has a dry matter (DM) of 6% and a nutrient profile shown in table 1. More dilute slurry (2-4 % DM) will have reduced N, P & K values which may result in the under fertilization of crops such as grass or maize silage if the slurry is assumed to have more typical nutrient content. These crops should receive a large proportion of their N, P & K in the form of slurry in 2022. Take slurry DM into account and make adjustments to application rates to ensure sufficient nutrients are applied to meet crop requirements during the growing season. The DM% of slurry can be measured on farm with a slurry hydrometer or alternatively by sending a sample of agitated slurry for nutrient analysis to a laboratory (N, P, K & DM%).

Step 2. Timing of Slurry Applications

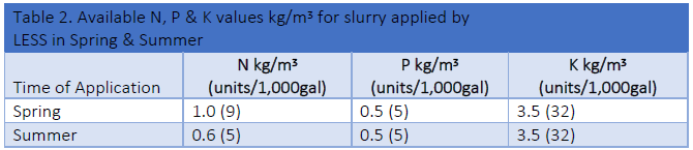

The second step to increasing slurry N efficiency is optimizing the timing of slurry applications. Spring applications of cattle slurry typically have higher recovery of N, by up to 50%, compared to summer applications (Table 2). Weather conditions in springtime will be more favorable to improving the recovery of N from the slurry. For example, during cool (< 13⁰C), damp, overcast days, N loss through ammonia emissions are lowest.

Step 3. Using the right equipment

Spring applications using LESS further increases N availability by 65% compared to summer applications. For example, where a grass silage crop receives 33mᶾ/ha (3,000 gallons/ac) in springtime, this will supply 33 kg/ha N (~25 to 30% of the crops N requirement). However, when applied in summertime it will only supply 20 kg/ha N.

Other benefits of LESS include

1. Improved flexibility with applications as a result of reduced contamination of herbage leading to quicker return to grazing;

2. Opportunity to apply slurry into larger grass covers which creates a wider window for application in better soil conditions particularly in spring;

3. More even application of slurry across the spread width;

4. Smells released during and after application are reduced.

Teagasc Slurry Spreading Calibration Tool

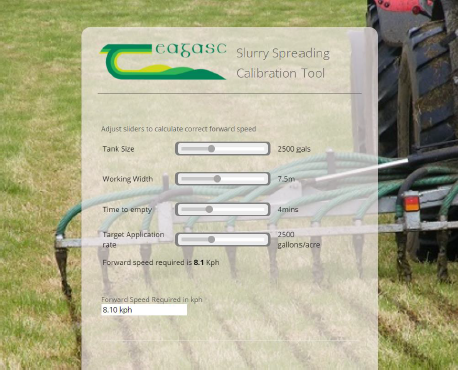

Teagasc have created a simple online calibration calculator to eliminate the guess work out of this. The tool can be used with any type of slurry tanker no matter what applicator is being used on the back. It works on you smart phone so it can be accessed from the tractor seat. It is simple to use:

1. sliders allow you to input the size of tanker, spread width and the time taken to empty the load.

2. Select you desired application rate

It will give you the correct forward speed needed. This will ensure you are making the most of the valuable fertiliser source. See Teagasc Slurry Calibration Tool

Getting the Best Out of Slurry