14 March 2021

Using LESS Gives More from Slurry

Cattle slurry is a valuable source of N, P & K produced on farm. Nitrogen (N) in cattle slurry is in a similar ammonia form to N in urea & is easily lost to the atmosphere. Teagasc Advisor Mark O’Sullivan has valuable information on the benefit of using trailing hose or trailing shoe to apply slurry

Slurry application techniques such as trailing hose or trailing shoe reduce the surface area of the slurry compared to the splash plate thus reducing the loss of N as ammonia to the air.

Nutrient Content of Slurry

The Nutrient Content of slurry can vary hugely. Two of the main factors influencing this is the:

- feed type given to the animals producing the slurry and

- the dry matter of that slurry when spread.

The Nutrient Value of this slurry to your grass fields is influenced predominantly by 2 things – weather and method of application. The traditional splash plate method gives the least value of nitrogen from slurry, whereas the trailing shoe method gives the most value—– this difference can be almost double. In other words, 1000 gals of slurry applied by trailing shoe can supply 12 units N/acre, compared to 6 units N/acre from splash-plate. Spreading in cool damp conditions gives the best nitrogen value from slurry with the least value coming from warm, dry conditions.

The P & K content of the slurry will equally be influenced by animal diet and dry matter or level of dilution of the slurry with water. However, the P & K value of the slurry is fairly similar regardless of method of application with typically approximately 5 units of P and 32 units of K in ‘average slurry’.

Ideally, a simple slurry test from your own tank(s) is essential to give you definite figures. This test costs approximately €60 per sample. It could be money very well spent in either saving you money on bagged fertiliser or growing more grass/silage by allowing you apply the correct bag fertiliser thereafter.

LESS Application is less Grass Contamination

LESS machines have the ability to significantly reduce grass contamination with slurry, compared to the splash-plate. This allows for a shorter interval between slurry spreading and grazing which is important during times of the year when grazing rotation lengths are short. Slurry can be applied to covers of up to 1,200 kg DM/ha with trailing shoe, whereas with the splash-plate we are confined to the paddocks with low grass covers to avoid grass contamination. This allows for more targeted slurry spreading to paddocks that need the slurry nutrients the most e.g. silage ground and fields in Index 1 and 2 for P or K.

The ability to spread slurry into higher grass covers also increases the area of the farm that can be spread with slurry in early spring when ground conditions allow. This has advantages in terms of increasing the amount of slurry that can be spread which can help to free up slurry storage during this period and increasing the amount of N capture.

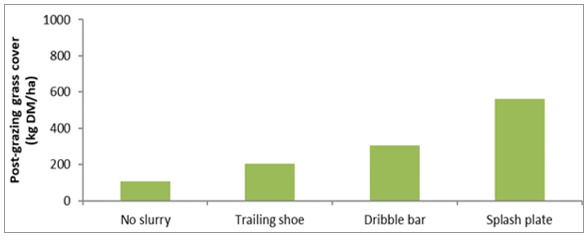

Recent demonstrations carried out by Teagasc has shown that cows prefer to graze pastures spread by either trailing shoe or dribble bar compared to splash-plate. For the demonstration, slurry was spread on three grass plots at a rate of 3,000 gal/ acre using splash plate, dribble bar and trailing shoe on the 9th March 2018. Cows were given access to the three plots 21 days later for a 2 hour grazing period. The cows could move and selectively graze which ever plot they preferred. The cows grazed the most grass from the trailing shoe plots followed by the dribble bar and then the splash-plate (Figure 1).

Figure 1. Post-grazing grass covers on field plots spread with slurry using different slurry application methods. Grass cover was 1,200 kg DM/ha at time of slurry spreading and grazing occurred three weeks after slurry spreading. Insert pictures shows level of grass contamination at time of slurry spreading

Top Tips for Utilising Slurry N Efficiently

- Apply to fields with a large nutrient demand i.e. Silage Fields

- Apply under cool & damp conditions

- Apply with trailing hose or shoe

- Dilution with water will increase slurry N efficiency

- Spring application is best

- Test slurry to determine nutrient content

- Adjust chemical fertiliser N rate & make cost saving