09 January 2022

Shelf Life of Food Products

The shelf life of a food product refers to the length of time for which it can be stored, under specified conditions, while remaining in optimum condition and safe for consumption. Find out about factors affecting shelf life, legal requirements for shelf life, use-by dates, and best-before dates.

Introduction

The shelf life of a food product refers to the length of time for which it can be stored, under specified conditions, while remaining in optimum condition and safe for consumption. The shelf life of a food begins from the time the food is produced and is dependent on many factors, such as the ingredients, processes, type of packaging and storage conditions. The shelf life will affect things such as stock storage times, delivery and distribution methods, and many retailers have very specific expectations in terms of the shelf life of listed products.

The shelf life of a food product refers to the length of time for which it can be stored, under specified conditions, while remaining in optimum condition and safe for consumption. The shelf life of a food begins from the time the food is produced and is dependent on many factors, such as the ingredients, processes, type of packaging and storage conditions. The shelf life will affect things such as stock storage times, delivery and distribution methods, and many retailers have very specific expectations in terms of the shelf life of listed products.

Food businesses are required to establish a safe shelf life for all of the foods that they produce, but it is also in the producer’s interest to ensure the sensory and physical quality of the product is retained over time and that any nutritional declarations remain valid. It is important to determine if the product(s) require a “best-before” or “use-by” date.

Factors affecting shelf life

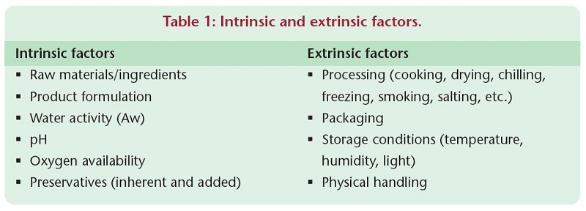

All foods have their own distinctive characteristics that will affect their shelf life. These can be broadly divided into intrinsic characteristics, which are inherent to the composition of the food, such as its ingredients and formulation; and, extrinsic characteristics, which relate to the external environment but have an impact on the food, such as the storage temperature and packaging. Some characteristics prolong shelf life while others decrease it.

Bacteria, yeast and mould growth can cause food spoilage or food poisoning. The time taken for microorganisms to spoil a food or to render it unsafe to eat can depend on: (i) the type of food; (ii) the level of microorganisms in the food after it is produced; (iii) any further contamination that occurs during subsequent handling, filling, packaging and storage; and, (iv) the time and temperature of storage.

There are many other ways in which the quality of a food can be lost over time. They may not necessarily result in the product being harmful, but can mean that it is no longer acceptable in terms of the taste, smell, appearance or nutritional content. Moisture loss or gain, exposure to light, temperature changes or physical damage to the packaging can result in the food losing its colour, turning rancid or losing its nutritional value.

Legal requirements for shelf life

A food must not be placed on the market if it is unsafe or unfit for consumption. The manufacturer of a food is responsible for setting and validating the shelf-life, either as a use-by or best-before date. Commission Regulation (EC) No 2073/2005 sets the legal microbiological criteria for a range of foods.

A food must not be placed on the market if it is unsafe or unfit for consumption. The manufacturer of a food is responsible for setting and validating the shelf-life, either as a use-by or best-before date. Commission Regulation (EC) No 2073/2005 sets the legal microbiological criteria for a range of foods.

Use-by date

Food products which, from a microbiological point of view, are perishable and therefore likely after a short period of time to constitute a danger to human health, must have a use- by date. The use-by date will indicate the date up until which the product can safely be consumed. Examples of foods that have use- by-dates include chilled dairy products, cooked meats and prepared salads.

Best-before date

The best-before date will reflect the quality (taste, smell, appearance) of the product(s) rather than the safety. A food which is past its best-before date may not necessarily be unsafe to eat, but it may no longer be of satisfactory quality. Typically, a best-before date is required on long-life products such as canned, dried and frozen foods.

How to determine the shelf life of a food product

A shelf-life study can be used to determine how long a product can reasonably be expected to retain its quality and safety. A separate study needs to be carried out for each type of product and the following steps can act as a guideline:

Identify what may cause the food to spoil or become unsafe.

Consider both the intrinsic and extrinsic factors (Table 1).

Select suitable testing methods

Sensory evaluation is used to assess the food’s smell, appearance, flavour, and texture for any changes over time to the point at which the food is no longer The food should be assessed under the intended storage and consumption conditions.

Microbiological analysis is used to evaluate both the quality and safety of the food by measuring changes in the number and types of spoilage organisms (yeasts, moulds or bacteria) over time. Identification of any food poisoning organisms present is important for food safety. The type of tests applied will depend on the particular product.

Chemical analysis is used to detect changes in the product over time, measuring characteristics of the food such as the pH (acidity), Aw (water activity) and free fatty acids (indicating rancidity).

Carry out the shelf-life study

- determine how long the study will last, what tests will be used and how often the food(s) will be tested

- testing should be carried out at the beginning (start of shelf life), at a number of timepoints over the storage time, and finally at a point beyond the expected shelf life to confirm it has expired

- testing should be performed on triplicate samples of the food at each timepoint

- the study should be carried out more than once to take account of variability of the product, seasonality, etc.

- the product, process and packaging should be the same as you intend to use for the final product

- the samples should be stored under the same conditions as your normal samples, from production through to consumption

- keep written records of everything you use or do, or have done.

Determine the shelf life

- using all the information you have recorded and observed, decide how long the product can be kept and still be of acceptable quality and safety

- maximum storage times for quality and safety may not be the same and the shelf life of the food should be whichever is shortest

- this estimated shelf life is based on ideal storage conditions, so you need to make allowances for a situation where the storage conditions may not be strictly observed and product abuse can occur, e.g., if a product is held in a warm car too long when transporting home from the supermarket

- the shelf life you select for your product should be reasonable, not ideal, and you should allow a safety margin.

Note: if the food or its production process is modified or changed, it will be necessary to re-evaluate the shelf life and adjust if necessary.

Fact sheet produced by the Food Industry Development Department. Download the factsheet as a PDF

For further information please contact Ciara McDonagh, Food Industry Development Department at: +353 (0) 1-805 9500 or ciara.mcdonagh@teagasc.ie

The following resource is also helpful: https://www.fsai.ie/faq/shelf_life/determination.html