Taking Advantage of Growth Rates

Taking Advantage of Growth Rates 01 June 2022 Type Media Article By Mícheál Kelly, B&T Drystock Advisor, Teagasc Galway/Clare The old saying goes that “a wet and windy May will fill the barn with corn and hay” and by all accounts, the current growth rates are living up to this saying, but whether or not […]

By By Mícheál Kelly, B&T Drystock Advisor, Teagasc Galway/Clare

Taking Advantage of Growth Rates

Type Media Article

By Mícheál Kelly, B&T Drystock Advisor, Teagasc Galway/Clare

The old saying goes that “a wet and windy May will fill the barn with corn and hay” and by all accounts, the current growth rates are living up to this saying, but whether or not the weather will play ball to allow the small square balers to be dusted off remains to be seen.

Early May saw huge rainfall but the corresponding high temperatures drove grass growth, with many silage slabs and yards filled in the last two weeks. Luckily the weather picked up to allow silage to be harvested just before grass started to head out, meaning silage quality on many farms for the most part will still be on track.

Depending on the variety, grass plants will enter the reproductive phase by producing a seed head somewhere between mid-May and mid-June, at which point the plant becomes stemmy and the dry matter digestibility of this grass as silage will be greatly reduced. The DMD value (Dry Matter Digestibility) is the percentage of silage dry matter consumed that is essentially digested by the animal and thus utilised by the animal. Therefore the higher the digestibility (DMD) of the grass silage, the more efficiently animals will use it and the greater the production e.g. meat, milk. Grasses with a lot of stem, seed-heads, dead vegetation or crop lodging are much less digestible than those with a greater proportion of leaf.

A delay in harvest date can quickly turn a highly digestible crop fit to fatten cattle into a poorer crop suitable only for suckler cow maintenance or less, as each week delay in harvest date see the DMD decline by 3.0 units. This means additional concentrates must be offered during the winter to maintain animal performance. Given the fertiliser prices this year, we all want to achieve a high yield but a balance must always be struck between quality and quantity and it seems a lot of farmers hit this nail on the head this year.

The cycle now continues and we must turn our attention to closing for second cut silage. Second cut silage is planned on many farms to help replenish silage reserves for the coming year. This crop is generally lower yielding compared to first cut silage. Where first cut has been cut its important to ensure that second cut crops are fertilised adequately to ensure a good yield at harvest time.

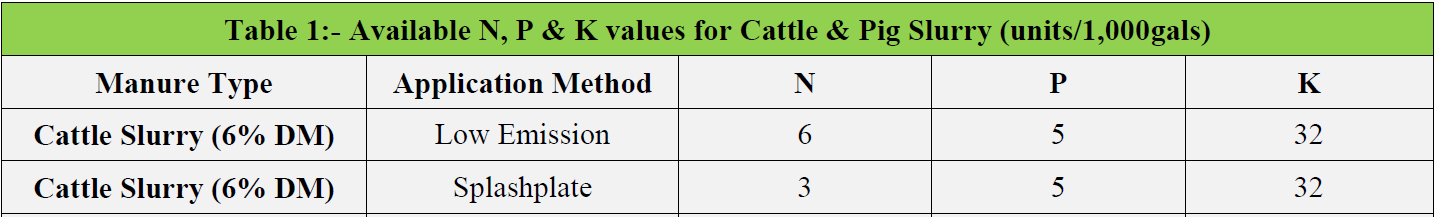

Cattle slurry may not have been applied to first cut silage crops due to weather and soil conditions. Aim to apply cattle slurry after first cut silage to replenish soil P and K removed. Where a second cut of silage is planned, consult with table 1 to see N, P & K manure replacement values. Maximise cattle slurry application at this time of the year so that slurry tanks are emptied before next winter. Cattle slurry applied by splashplate in June will have a lower nitrogen (N) value compared to low emission application techniques see table 1 below for N values.

Table 1: Available N, P K values for Cattle & Pig Slurry (units/1,000 gallons)

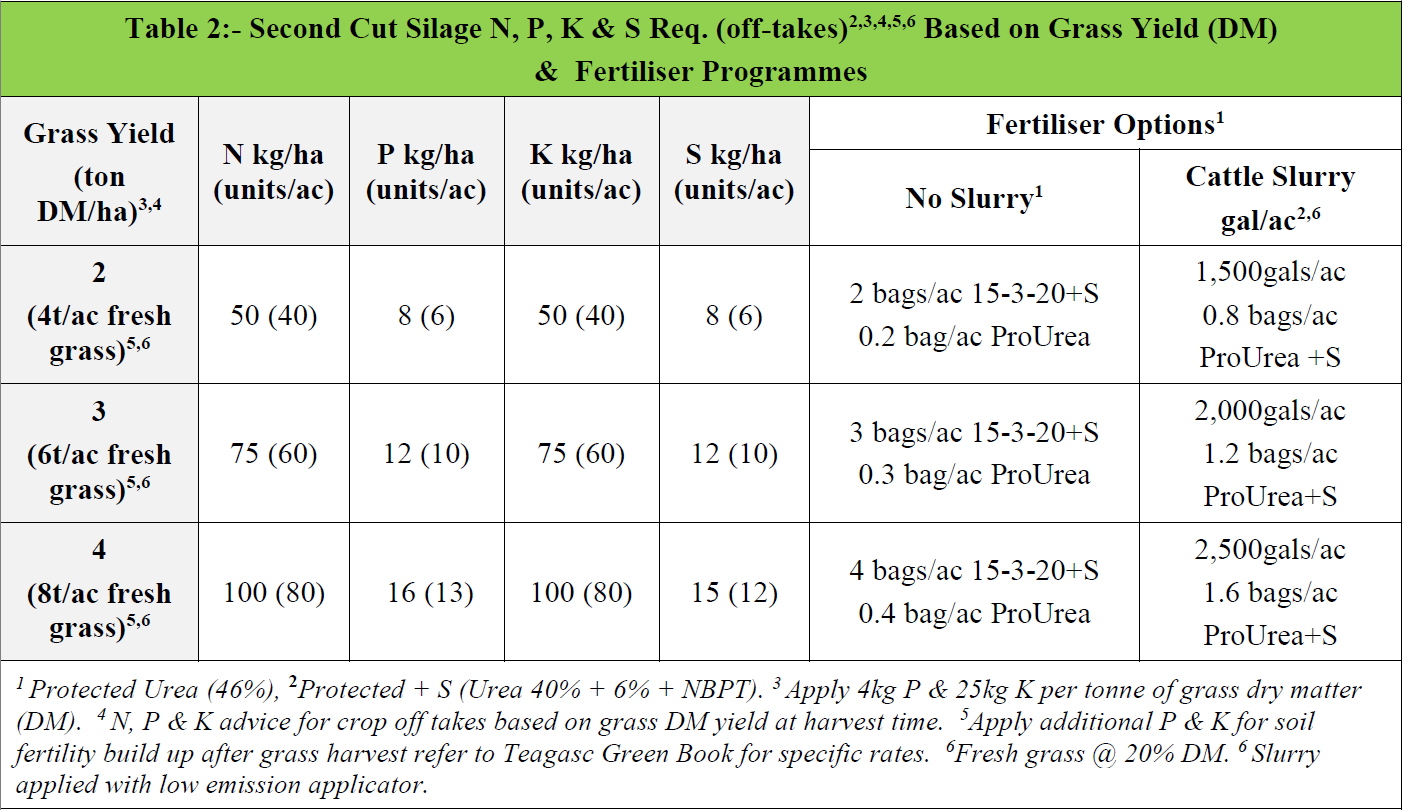

Fertilise second cut grass silage based on crop yield potential. Table 2 below shows the fertiliser requirements based on a grass dry matter yield of 2 to 4t DM /ha (4 to 8t fresh grass/ac). Suggested fertiliser programmes are shown with and without cattle slurry.

Don’t Forget Sulphur (S) – Key role in increasing grass DM yield, Fertiliser N efficiency and reducing N leaching. For 2nd cut grass silage crops apply 8 to 15kg S/ha (6 to 12 units/ac) per cut.

Liming – Where soils test results indicate that fields have a requirement for lime, lime may be applied after first cut silage if the same fields are not being closed for a second cut as the grass covers will be at their lowest. If lime were to enter the silage pit or be picked up in bales, it may affect preservation by counteracting the acidic conditions required for good fermentation. Where slurry has to be spread, the slurry should be applied first and the field can then be limed 7-10 days later. This will minimise N losses from the slurry. Slurry and urea should not be spread for 3 months after liming to minimise N losses. However, no interval is required between liming and the spreading of protected urea.